Interested in Headworks?

Get Headworks articles, news and videos right in your inbox! Sign up now.

Headworks + Get AlertsBelt Filter/Rotary Presses

BDP Industries 3DP Belt Press

The skid-mounted 3DP Belt Press from BDP Industries is a turnkey dewatering solution with all components integrated on a hot dip galvanized skid for easy semi-permanent installation. This skid includes a booster pump, sludge pump, emulsion polymer system, hydraulic unit, controls and a 20-foot stainless steel screw conveyor. The press includes an independent gravity section, vertical pressure section and paddlewheel distributor. Features addressing odor control concerns include odor hoods, enclosed gravity sections, piped away filtrate and noise-reducing shower boxes. 518-695-6851; www.bdpindustries.com

Bright Technologies, Division of Sebright Products, 0.6-meter skid-mounted belt filter press

The compact 0.6-meter skid-mounted belt filter press from Bright Technologies, Division of Sebright Products, has stainless steel frame and roller construction as well as radius wedge zone and wing roller for sludge dewatering. Components include a sludge pump, polymer system and wash-water booster pump. Options include a sludge flowmeter, air compressor and discharge conveyors. With a compact, walk-around skid design, it can be utilized in as little as a 10-by-20-foot floor area. The Boerger rotary lobe sludge pump has a maintain-in-place design offering ease of maintenance. Cake solids of up to 35% can be achieved. Rates of 25 to 50 gpm make it ideal for small applications or when a processor has outgrown dewatering containers. 800-253-0532; www.sebrightproducts.com

Biosolids Handling/Hauling/Disposal/Application

Boerger BLUEline rotary lobe pumps

Boerger BLUEline rotary lobe pumps are a self-priming, valveless, positive displacement pump used for conveying viscous and abrasive materials. They are resistant to wear and provide pulsation-free operation. Operation is fully reversible, with dry run capability and flow rates up to 7,000 gpm. They are constructed with maintenance-in-place design, allowing for all wetted parts to be easily replaced through the front cover without removing pipe or drive systems. The pump conveys biosolids (primary, waste activated sludge, return activated sludge, digested, thickened, etc.), grease, sewage, scum, lime slurry, alum sludge, permeate and polymers. 612-435-7300; www.boerger.com

ELODE USA Electro-Osmosis Dehydrator

The compact Electro-Osmosis Dehydrator from ELODE USA can easily retrofit in line with many existing presses. It is specified to reduce sludge disposal cost by 60% by producing much drier sludge cake. It uses the electrical potential difference in the sludge cake to separate water in the process and it works on 95% of municipal cakes tested without any chemical, polymer, heat nor mechanical press. It can be used to turn 15 to 20% DS cake to 40 to 45% DS quickly. 201-568-7778; www.elodeusa.com

Paxxo Longopac Fill

The Longopac Fill continuous bag system from Paxxo can connect to the discharge point of machines used to move, dewater or compact screenings, grit and biosolids. Material is then deposited in a 90-meter-long continuous bag for odor containment and spillage control. The cassette bag can be sealed with ease, and the material and odors are trapped inside, cutting down development of bacteria and fungus spores. 770-502-0055; www.paxxo.com

SRS Crisafulli FLUMP dredge

The FLUMP unmanned remote-control dredge from SRS Crisafulli removes biosolids and sediments. It is easy to use from a workstation or mobile phone, and easy to transport at approximately 6,000 pounds. It delivers lower operator exposure to potentially hazardous materials, high performance with minimum turbidity, and faster operations with high-speed reverse and pivoting traverse systems. Its pumps are manufactured with an ASTM AR400 mild carbon steel (BHN 400 hardness) pump volute and impeller, and dual carbon/ceramic shaft seals. The pump is mounted directly behind the cutterhead and is lowered into the pond on the dredge’s ladder. Standard, severe-duty or custom models are available. 800-442-7867; www.crisafullipumps.com

Biosolids Heaters/Dryers/Thickeners

JDV Equipment Sludge Heater and Exchanger System

The Sludge Heater and Exchanger System from JDV Equipment ensures optimal thermal efficiency for anaerobic digestion. The counter-flow tube-in-tube Ralph B. Carter design promotes high-efficiency heat transfer with minimal fouling to recirculated biosolids. The integrated three-way blending valve maintains a uniform inlet water temperature for increased digester operational efficiency. Each system is manufactured to ASME standards. 973-366-6556; www.jdvequipment.com

Veolia Water Technologies BioCon ERS

Rising concern of PFAS contamination of water and soil has sparked interest in this emerging contaminant as it pertains to wastewater sewage sludge. BioCon ERS from Veolia Water Technologies offers a safe and sustainable drying and combustion system for treating PFAS-laden municipal biosolids. It combines the efficiencies of a convective air medium-temperature belt dryer with a biomass furnace, which uses the dryer output (dry product) as a biofuel. The heat available in the exhaust is captured and used as process heat in the belt dryer. This integrated dryer and energy recovery system is sustained by heat generated by the combustion of biosolids to drive the drying process, and in turn the dried material fuels the combustion system, making it a fully energy sufficient and sustainable operation. It combusts sludge between 1,400 and 1,800 degrees F, which is higher than the minimum temperature required for PFAS destruction. 919-677-8310; www.veoliawatertech.com

Chemical/Polymer Feeding Equipment

Blue-White Industries FLEXFLO M4

The low-shearing pumping action of FLEXFLO M4 peristaltic dosing pump from Blue-White Industries allows it to gently and precisely pump chemicals that off-gas, including peracetic acid and sodium hypochlorite, with no vapor lock and no lost prime. Advanced features include a highly responsive and intuitive 5-inch display, firmware that can be field updated, and easy-to-attach M12 watertight connectors. 714-893-8529; www.blue-white.com

Force Flow Tote Bin Scale

The Tote Bin Scale from Force Flow allows plant operators to accurately monitor the amount of polymer being fed from IBC-type totes for dewatering. Simply place the tote on the platform and monitoring begins, as there is nothing to install inside the tote. Monitoring systems prevent costly overfeed conditions and enable the documentation of the actual amount fed, which keeps the plant in compliance with federal and state reporting requirements. Users can remotely monitor from SCADA or PLC. The unit is available with the SOLO G2 digital display or with the advanced Wizard 4000 chemical inventory management system. 800-893-6723; www.forceflow.com

Lutz-JESCO America LJ-PolyBlend Polymer System

The LJ-PolyBlend Polymer System from Lutz-JESCO America is a dependable, motorized mixing machine with a corrosion-resistant housing, large turbine and multizone mixing chamber that provides uniform dispersion energy at the moment of initial polymer wetting. The prime mixing zone fully activates the polymer, while the second mixing zone promotes gentle polymer activation via a small turbine, lessening molecule fracturing. Its stainless steel injection valve prevents agglomerations and reduces the need for extended mixing time. The system includes a clear mixing chamber that provides visual monitoring of mixing polymer feed. Its compact design — only 1 to 1.5 square feet — means it’s light and allows for easy installation and transportation. It has automatic pump speed adjustment via 4-20mA input, water flow sensor and priming port. 800-554-2762; www.lutzjescoamerica.com

Coagulants/Flocculants

Nanozyme Technologies Clean H2S

Nanozyme Technologies Clean H2S is a catalytic enzyme consortium that continues to work long after it is applied throughout the system. It is designed to quickly bring the whole system into accepted values on an ongoing basis. It is typically applied in a vapor phase for large volumetric spaces like press rooms, but it can also be directly injected into air moving piping and equipment with dramatic effect as seen here. This technology is personnel and environmentally safe, and is organic and botanically derived. There are no living bacteria present. Each air quality system is designed for each specific application. 860-305-9881; www.nanozymetech.com

Next Filtration Next-F.O.G.Stop

Next Filtration’s Next-F.O.G.Stop is molecular kinetic technology that optimizes aerobic MLSS operation and increases wastewater throughput up to 40%. It promotes biostimulation of indigenous microorganisms through the uncoupling of microbial metabolic pathways. Trials demonstrate that it amplifies the metabolic rate of organic carbon degradation and lowers the amount of biomass produced. The excess carbon is metabolized and off-gassed in the form of carbon dioxide rather than being converted to biomass or biofilm. Specifically, results show feeding it into the inlet stream of municipal and industrial wastewater facilities led to a decrease of biological oxygen demand and total suspended solids, and an increase of dissolved oxygen. Indirectly, this leads to reduced energy consumption, due to reduced aeration blower rates. 800-783-0310; www.nextfiltration.com

Dewatering Equipment

AQUA-Zyme Disposal Systems ADS

The ADS 30-yard open-top roll-off dewatering unit from AQUA-Zyme Disposal Systems can be filled with 22,000 to 25,000 gallons of biosolids at 1% to 2% solids in about two hours. After draining for 24 hours, the unit can be picked up using a standard-capacity roll-off truck and transported for solids disposal. Sludge volume can be reduced by 80% with reductions to 98% in BOD, COD, FOG and TSS. Effluent is clear, the unit has few moving parts, and the size of filter media can be selected according to job requirements. Standard equipment includes a roll-over tarp system; side, floor and center screens; 1/4-inch floor plate; 7-gauge side plates; four door-binder ratchets; eight drain ports; two inlet ports; and a long-handle scraper. Units are also available in a 15-yard size. 979-245-5656; www.aqua-zyme.com

In the Round Dewatering horizontal drum

The horizontal biosolids dewatering system from In the Round Dewatering features a stainless steel drum with perforated plastic tile lining. The drum is mounted on a roll-off frame for easy transport and unloading. Trays contain discharge water. An 18,000- to 25,000-gallon batch is mixed with polymer before being filtered in the rotating drum, which is driven by a 1/2 hp variable-speed electric motor with a heavy-duty chain and sprocket. Turning eliminates crusting and wet pockets to produce uniform, consistent results. The dewatered material dumps easily, and the drum is self-cleaning. 317-563-2072; www.itrdewatering.com

Park Process SludgeKing II

The SludgeKing II roll-off dewatering container from Park Process incorporates an engineered design that eliminates trapped water in the bottom of the filter cake. The second center wall filter increases filter area by 33% producing drier cakes in less time. The plastic floor panels that cover the floor space between wall filters and center wall filters serve three purposes. They hold down the bottom of the filter elements, help eliminate standing water and aid in filter cake dumping. The inlet manifold is split into three inlets, each with a ball valve, allowing incoming flow to be distributed evenly into the three compartments formed by the two center-wall filters. 855-511-7275; www.parkprocess.com

Digesters

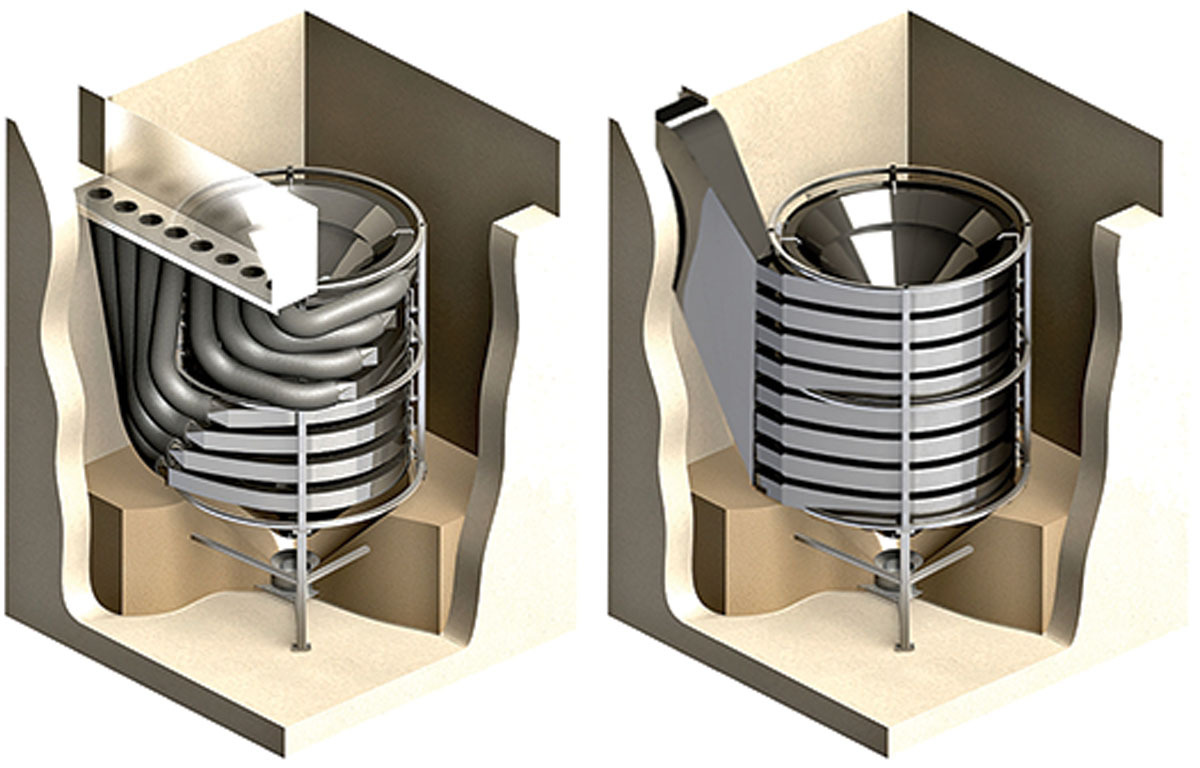

Anaergia Omnivore

The Omnivore is Anaergia’s high solids approach to anaerobic digestion. It incorporates advanced mixing and robust thickening systems to convert low-solids digesters into high-solids digesters (5 to 8%). It adapts to take on increased sludge loading without requiring new construction and supercharges biogas and energy projects by enabling co-digestion of high-strength waste. The system consists of a screw thickener combined with the OmniMix, a high-performance submersible mixer that delivers 30,000 gpm of flow, with a connected load of only 12.5 kW and an average power draw of 6 kW and can mix solids up to 12%. It features a gearless direct drive motor and a dynamic mixer that allows operators to adjust the mixer position to break up floating layers and re-suspend grit. The service box lets operators access the mixer without taking the digesters out of service, streamlining O&M. 866-978-9785; www.anaergia.com

Grinders/Shredders

Vaughan Chopper Pump

Self-priming Chopper Pumps from Vaughan are designed to be easily accessed outside of the wet well while pumping waste solids at heavy consistencies, without plugging or dewatering of the solids. They eliminate the loss in production and mess, along with making it easy to service the pump to get it back in operation. 888-249-2467; www.chopperpumps.com

Grit Handling/Removal/Hauling

Envirodyne Systems OctoCell

The OctoCell grit removal system from Envirodyne Systems utilizes stacked trays to achieve a small footprint. Unique to their design is the ability to provide either the conventional vertical chute entry, or a horizontal inlet trough and tentacle arrangement above the trays. With the latter configuration, trays are engaged/disengaged based on actual flow. Other features include the visual detection of any plugging, and a means of active or passive control of flow to each individual tray for enhanced control of velocities and reduced organics accumulation. 717-763-0500; www.envirodynesystems.com

Hydro International Compact Grit Removal

Hydro International’s line of Compact Grit Removal is designed to meet the flows, treatment needs, and budgets of smaller wastewater treatment plants. Engineered for low maintenance and high performance in a small footprint, the flexible layout options make it the ideal fit for even the smallest plants. Configured to seamlessly fit within existing infrastructure and without the need for a long approach channel, our line is easy to install and minimizes construction costs. With Grit King Compact and SpiraSnail Compact (or Decanter) dewatering, small plants can realize the benefits the proven protection advanced grit management provides. The systems are built for the specific needs of smaller treatment plants. As a result, high performance grit removal is available to smaller plants at a price point and size that is within reach. 866-615-8130; www.hydro-int.com

Smith & Loveless PISTA INVORSOR

Inspired by extensive expert CFD modeling and developed rigorously in actual field conditions, the PISTA INVORSOR grit removal system from Smith & Loveless combines the power of proven particle capture methods: enhanced settling by inclined plates meeting a defined surface overflow rate with the established hydraulic forced vortex to achieve ultra-fine grit removal efficiency down to 75-micron particle size across all flows with no derating. It helps deliver lower capital and operational costs, larger capacity in individual units, greater design flexibility for inlet-outlet design options, and a higher surface area-to volume ratio to generate consistent fine grit capture during low flow, daily flow and peak flow conditions — up to 50 mgd in single units. 800-898-9122; www.smithandloveless.com

Trillium Flow Technologies WEMCO Hydrogritter

The WEMCO Hydrogritter from Trillium Flow Technologies is a grit cyclone and classifier with an operational life of over 25 years at low operating and maintenance costs. The system removes and dewaters grit from primary sludge or influent and can process from 220 to 1,570 gpm per cyclone at a pressure of 5 to 20 psi, which allows for a grit withdraw rate of 3/4 to 8 1/2 tons per hour at a 1% grit concentration. Typical configurations have one to four cyclones per classifier, allowing for maximum flexibility to meet grit removal needs, removing remove fine (+150 mesh) grit. 559-442-4000; www.trilliumflow.com

Screw Conveyors

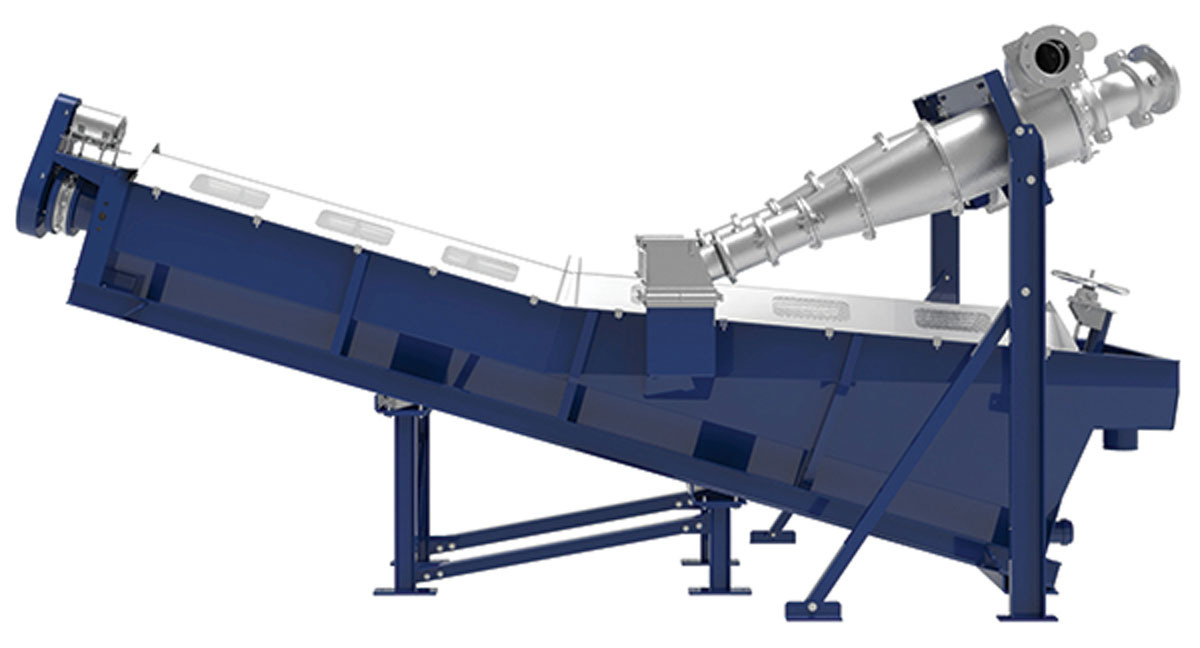

Charter Machine Royal Screw Press

Charter Machine’s Royal Screw Press offers a small footprint and high-efficiency design that has very low power consumption with a higher throughput. Using an integrated thickening drum, the system can concentrate feed solids up to 5% DS. The complete skidded system is ultra-quiet, large capacity and low-maintenance. The removable washwater nozzle ring travels, with its self-cleaning nozzles, laterally the length of the drum and gives a maximum clean with minimum amount of water. The sleek skidded design includes controls, drum thickener, sludge concentrator tank, sludge pump and screw press. 732-494-5350; www.chartermachine.com

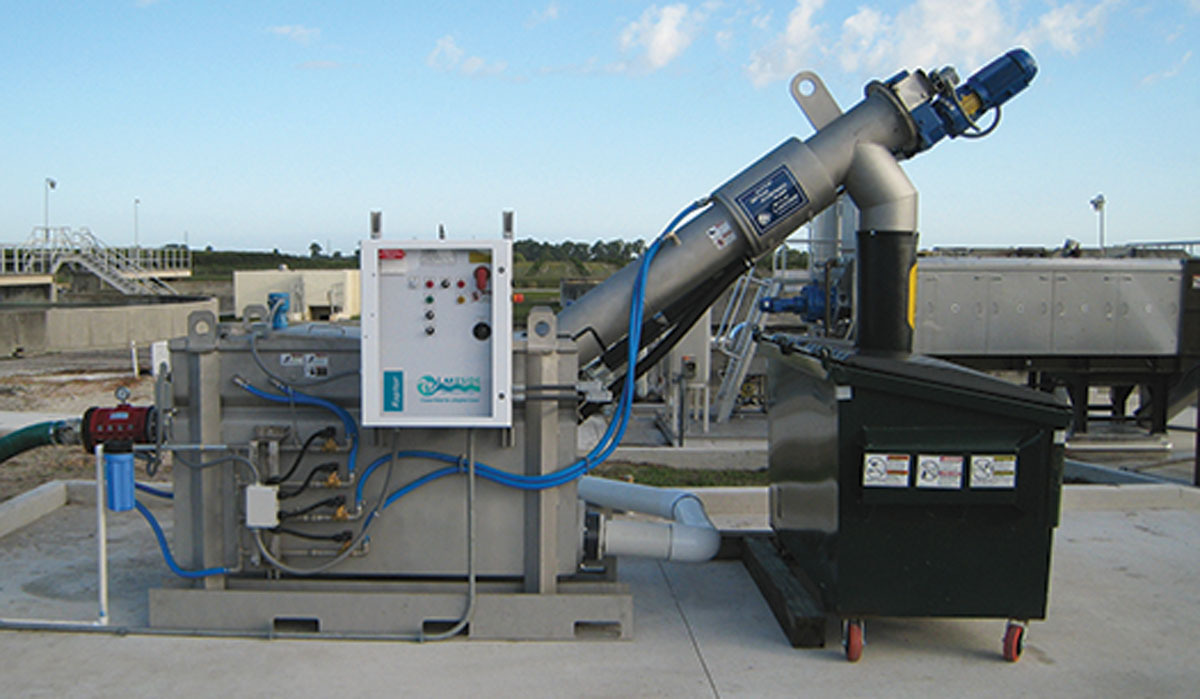

Headworks International Screwpactor

The Headworks International Screwpactor shafted spiral washer compactor is available in three models for wastewater screenings, washing and handling applications. It is designed to receive screenings through conventional conveyance or sluicing applications. Solids enter through an inlet hopper and are conveyed by a shafted spiral where organics are washed and reintroduced into the treatment process. The washed screenings are conveyed through to a press zone where they are compacted into plug form and discharged into a bin or dumpster. Shafted Spirals are available in alloy or stainless steel. It offers throughput capacities up to 250 cubic feet per hour, and is capable of handling bricks, plastics and timbers. Optional heat tracing and continuous bagging units are available. 713-647-6667; www.headworksintl.com

Septage Receiving Stations

JWC Environmental Honey Monster

The Honey Monster septage receiving station and FOG receiving system from JWC Environmental is designed to ease the management of septage waste for the wastewater plant operator and the hauler. It quickly screens and processes septage, grease, FOG and sludge from vacuum trucks. The automated septage acceptance plant provides for cleaner handling of septage truck waste by reducing and separating unwanted solids such as rocks, rags, clothing, plastics and other trash, according to the maker. The combination of grinding, solids removal, washing and dewatering allows a typical septage truck to unload in 5 to 15 minutes. It is completely enclosed to ensure safety, vector control and containment of foul odors. The optional MonsterTrack metering and control system uses a flowmeter to track septage and provide accurate billing data for the facility and a receipt for the hauler. 800-331-2277; www.jwce.com

Lakeside Equipment Raptor Septage Acceptance Plant

The fully automated Raptor Septage Acceptance Plant from Lakeside Equipment is designed to remove debris and inorganic solids from septage tanks, grease traps, sludge, leachate and industrial waste. It includes the Raptor Fine Screen, which compacts and dewaters the captured screenings to a solids content of 40%. The screen’s rotating rake teeth penetrate the cylindrical screen bars, which prevents plugging and binding from grease and small debris. This allows for faster unloading times. The Raptor Acceptance Control System is a security access station that can be integrated to allow authorized haulers to unload their waste at the facility. Adding the data management and accounting system with the RACS station provides capabilities to track and invoice customers. 630-837-5640; www.lakeside-equipment.com

ScreencO Systems Trash Master 600 Auto Screen

The Trash Master 600 Auto Screen from ScreencO Systems uses gravity to separate the trash from the flow stream through a 6-inch inlet with dual fan spreaders. It is capable of power-offloading vacuum trucks with a single 6-inch offload or 2- to 4-inch offloads at the same time at a rate of up to 800 gpm. It comes with an aluminum hopper (stainless steel is optional), with an 8-inch outlet cam and 3/8-inch gapped 1/4-inch stainless steel bar screen. The stainless steel U-channel with ultra high molecular weight polyethylene plastic-lined titanium provides for years of wear, with a high strength alloy steel 11 1/2-inch shaftless screw that moves trash to a waste container. The U-channel has slotted drain holes and a center channel bar screen for cleaner and dryer trash. A custom-built stainless steel bar rake and cleaning brush are included for easy maintenance. 208-790-8770; www.screencosystems.com

Screening Systems

Evoqua Water Technologies Forty-X Disc Filter Armor Series

The Forty-X Disc Filter Armor Series from Evoqua Water Technologies is a high-rate filtration device that utilizes an integrated pre-screen and stainless steel panels that are designed to accommodate high solids loading capacities and greater hydraulic throughput. The woven optimum primary mesh filter panel utilizes 316L stainless steel threads to create a weave that improves solids collection and rejection, which makes this disc filter suitable for stormflow applications. The panel configuration includes a molded structural frame and pressured assisted seal, allowing the panels to sustain and operate at a higher headloss and provide higher throughput when compared to other disc filter synthetic media. The series combines the technology of outside-in and inside-out filtration into a single PLC-controlled unit with influent water flowing through the prescreen (outside-in) into the disc filter panels (inside-out). This combination of two filtration technologies provides an effective option for challenging applications. 844-409-9492; www.evoqua.com