Interested in Valves?

Get Valves articles, news and videos right in your inbox! Sign up now.

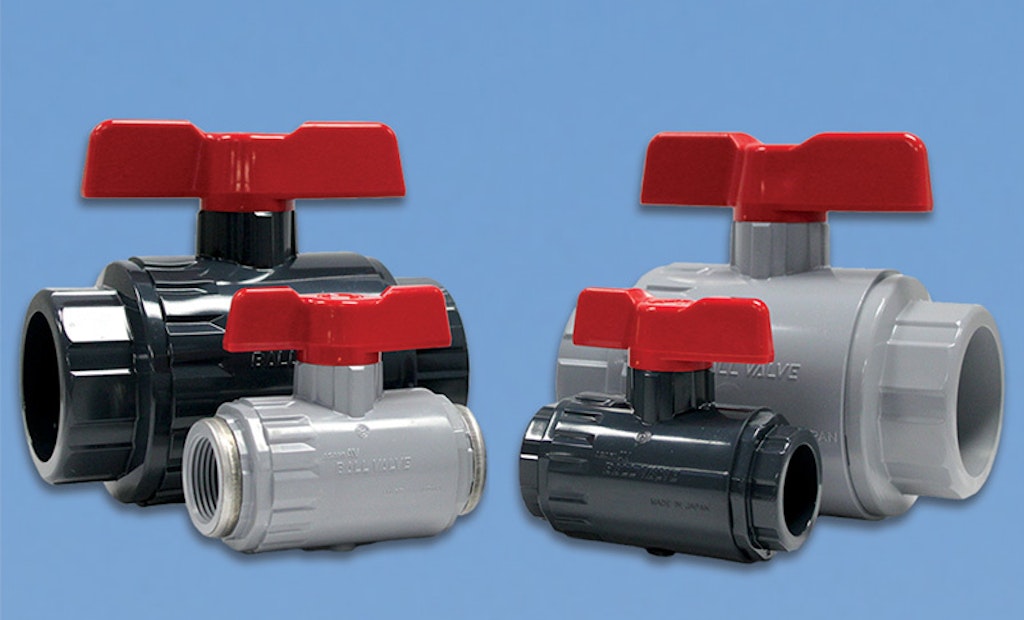

Valves + Get AlertsAsahi/America’s Omni ball valve is well known in the water and wastewater industry. It’s likely that anyone who performs maintenance at a plant would recognize it. However, as tooling changes, there’s often a need to update materials to match. Asahi/America’s Omni Type-27 makes those needed updates, while providing the same characteristics the Omni name has become known for.

“The Omni ball valve has been in existence since the 1970s,” says Dave Hurley, valve product manager for Asahi/America. “For the Type-27, the body was redesigned to accept an ISO 5211 bolt pattern mounting plate for actuation mounting. Also, the stem was upgraded to feature dual O-ring seals with stem shear protection, the ball opening was enlarged to be considered a full port ball opening, and Teflon seats were redesigned to withstand higher velocity.”

Ideal for water treatment, landfills, aquariums, chemical processing, power plants, swimming pools, water features and fountains, the Omni Type-27 can be electrically actuated with Asahi/America’s Electromni Series 83 electric actuator.

“It’s really a fit anywhere a ball valve is needed,” says Hurley. “It is ideal for OEMs and skid units, as the compact size and rugged design provide a quality valve for long life. This could be treated or untreated water and also chemical feed such as sodium or potassium hydroxide.”

The Type-27 ball valve is available with socket or threaded end connections in 3/8 through 2 inches. Available body materials are PVC and CPVC, both with EPDM seals and PTFE seats. It is NSF-61 certified and rated for 150 psi at 70 degrees F. According to Hurley, it is relatively new to the market.

“It was actually introduced in March 2017, so it is very fresh,” he says. “It is designed as a durable valve with lower costs and virtually no maintenance. A short face-to-face dimension permits installation in tight locations.”

Despite its recent debut, Hurley was able to get the valve in potential customer hands at a spring tradeshow, and the response was positive.

“Well we have had no complaints,” he says. “Potential customers liked the newly designed handle, the robust feel of the valve body, the smooth stem torque and that the valve is truly designed for automation with the ISO bolt pad attachment,” he says. “The valve has an engineered look and feel, and functions at a high level.” 800/343-3618; www.asahi-america.com