The ResidualHQ technology continuously samples and measures the chlorine and uses a feedback loop to add disinfectant as required.

Interested in Instrumentation?

Get Instrumentation articles, news and videos right in your inbox! Sign up now.

Instrumentation + Get AlertsChlorine residual is a critical variable in water distribution systems that often is monitored and controlled less than optimally.

Chlorine-based disinfectants degrade over time, and in areas of the system with low-volume usage, or at the end of long distribution lines, the residual can fall below the required level.

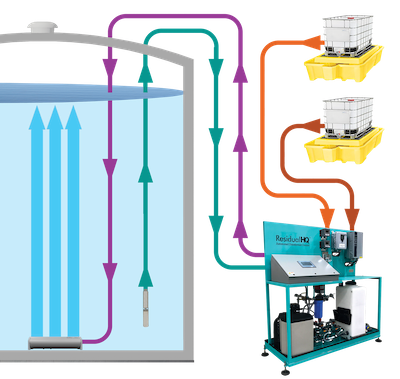

Now Ixom Watercare offers the ResidualHQ continuous residual monitoring and disinfectant delivery platform for chlorine or chloramine systems. When added to elevated or ground-level water storage tanks, it automatically maintains a preset level of disinfectant residual, saving on chemicals and minimizing disinfection byproducts.

The system continuously samples and measures the chlorine and uses a feedback loop to add disinfectant as required. Active mixing ensures that disinfectant is uniformly distributed throughout the tank contents.

The technology tracks disinfectant residual levels and trends and enables users to easily adjust parameters such as action thresholds, feed concentrations and feed ratios. The system is designed to be easy to maintain and to require infrequent system checks and calibrations.

It comes with tiered-access security and can be controlled on site or remotely. Emil Anheluk, marketing manager with Ixom Watercare, John Zent, innovation manager and Doug Kadrmas, electrical engineer, talked about the technology in an interview with Treatment Plant Operator.

TPO: What was the impetus behind bringing this technology to the market?

Anheluk: When water leaves the treatment plant and enters the distribution system, the disinfectant residuals started to degrade. Especially where customers have long distribution lines and dead ends in the system, it can be a real challenge to keep the disinfectant residual up to the legal limit. To compensate, they may increase the disinfectant dosage at the plant in hopes that the residual makes it to the end of the line.

Zent: To deal with that, a number of utilities will flush the system, opening hydrants to get more freshwater coming through and increase the residual at those locations. So a lot of water is wasted to get the residuals up. ResidualHQ was born as a solution to problems like those.

TPO: Where in the water system does this device operate?

Zent: Our equipment is most often installed at storage tank locations. There we can get the residual boosted back up and maintained at the level the customer needs, and from there feed into the distribution network. When a tank isn’t an option, the ResidualHQ can also be configured for use most anywhere along the pipe.

TPO: What parameter triggers the system to feed disinfectant into the tank?

Zent: The system monitors the chlorine level. A continuous circulation loop delivers water from the tank to the ResidualHQ unit. From there a pump returns the water to the tank. Off that circulation loop we sample the water by passing it over a reagentless sensor that monitors total and free chlorine. If the residual falls below the preset level, the unit automatically switches over to dosing chlorine into that circulation loop.

TPO: What hardware is included in order to dose the chlorine or chloramine?

Zent: There are basically three items. One is a submersible sample pump that takes the water from the tank and delivers it to the ResidualHQ. Then the ResidualHQ has its own pump that delivers water back to the tank. We also have a mixer that blends the entire tank to keep the contents homogeneous.

Anheluk: It’s important to note that when dosing chlorine we do not deliver what one would call a hot dose. We are very measured and stair-stepped as we achieve the setpoint the customer has chosen. We bring the chlorine into a pre-mix tank to dilute the disinfectant, be it chlorine or chloramine, to desired strength parameters. We use soft water to eliminate scaling issues.

TPO: How is the disinfectant actually delivered into the circulation loop?

Zent: There is no metering pump. The constant circulation loop provides a motive flow through a venturi to create a vacuum, which is then connected to the chemical source. We control that through a solenoid valve. The valve opens to allow the chemical in and is closed when dosing is not required.

TPO: What are the benefits of the technology beyond maintaining the required residual?

Anheluk: If you’re able to manage residuals throughout the system, you use less disinfectant. That saves money on chemicals and also reduces DBP formation.

TPO: What is involved in operating the system?

Zent: It’s an automated system, so once they determine the target residual and select a setpoint, it’s almost as simple as that. Based on our testing and field startups, there is a factory setting that largely works almost everywhere we go. There is some fine-tuning, and then they basically operate it from there.

TPO: What regular maintenance is required?

Zent: All they really have to do is check the calibration. They may take a sample every month to verify that the sensors are on track. After three to six months the sensors should be calibrated. Other than that, the system pretty much operates itself.

TPO: How do operators observe and control the system?

Zent: The main control console has an HMI. One of the main screens is a dashboard of the entire system, and other windows enable users to look at the process in more detail.

Kadrmas: ResidualHQ is intended to function like a headquarters. It is SCADA-compatible, but if the operators don’t have a SCADA system, it works as a stand-alone unit. It has trend lines and error logging, and other sensor inputs such as tank water level can be fed into the system. Remote monitoring is an option, so that from anywhere they have an internet connection they can log in, see their residuals or remotely control their unit.

Anheluk: The system is built with safety in mind. Many failsafes are built in to make sure it does exactly what it’s supposed to do. If the system gets a hint that something is off, it shuts down and triggers an alarm.