Interested in Odor Control?

Get Odor Control articles, news and videos right in your inbox! Sign up now.

Odor Control + Get AlertsGeomembrane covers solve odor issue in wastewater plants

Problem

Laguna Madre Water District in Port Isabel, Texas, sought to eliminate odor complaints after a high-end housing development was built next to the primary treatment plant. “We had all this new construction getting closer and closer to the plant, and we were concerned about keeping the nuisance odors within our buffer zone,” says Charles Ortiz, district engineer. Offsite odors at the worst point averaged above 88 ppm just above the channel surface; peak spikes registered above 860 ppm.

Solution

Anue Water Technologies provided a breathable geomembrane solution, enabling effective treatment without changing the plant footprints or operations. The flexible geomembrane system has a breathable design where pockets in the material contain replaceable carbon-infused filters that allow water and air to pass through, but trap the odorous compounds. No special equipment was needed to install the customized solution.

Result:

The membranes lowered odor levels to an average of 1.2 ppm; all offsite odors were eliminated. “We still have a little tweaking to do here and there — nothing is perfect, but as odor controls go, I would say that the system has done its job,” says Ortiz. 760-727-2683; www.anuewater.com

Covers eliminate odor from screw pumps

Problem

The St. George (Utah) Water Reclamation Facility houses 82-foot Archimedes screw pumps that are the longest in the world. The potential for hydrogen sulfide buildup in pumps stations required an odor containment and mitigation system.

Solution

Flight Dek Covers modular and lightweight covers from Epic International were custom manufactured for the screw pumps. The covers are made of pultruded fiberglass and weigh 75% less than steel and 30% less than aluminum. OSHA required 30 psf load-bearing capacity. Non-slip grit factory molded into the cover’s surfaces satisfied another OSHA requirement. The covers are UV stable and reduce screw pump thermal expansion. Interlocking joints between sections contain the odor and mist. An air-handling system safely vents the gases.

Result:

The covers contained the odor by easily integrating with an air venting system. 804-798-3939; www.epicintl.com

Plant uses analyzers to simplify chloramination monitoring

Problem

When the Milwaukee Water Works invested more than $250 million in water infrastructure and advanced water treatment, the process included converting from chlorine to ozone disinfection with chloramine as a secondary disinfectant. Operators quickly discovered the difficulty of maintaining precise ratios of chlorine and ammonia, which requires feed rate monitoring or grab-sample analysis. The chloramination monitoring system proved unreliable and required frequent maintenance.

Solution

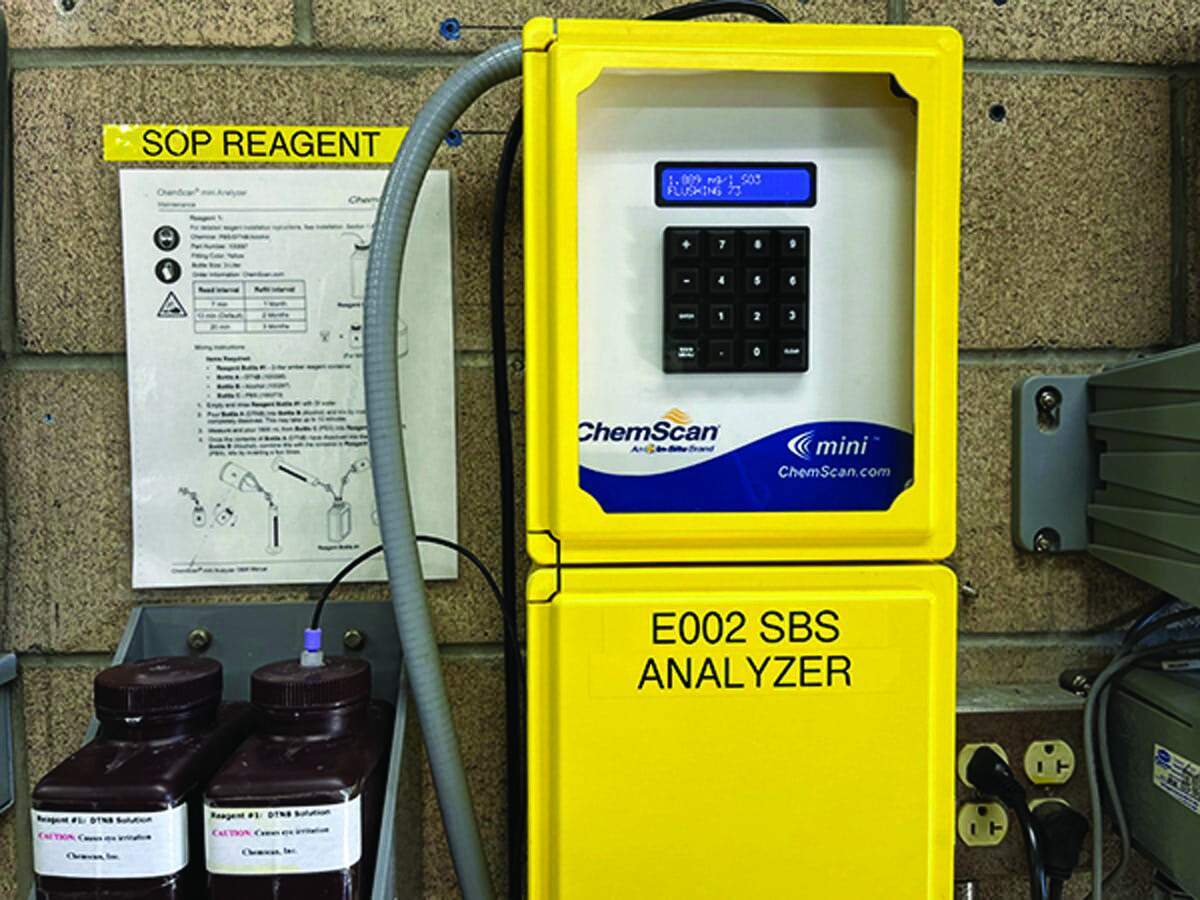

The utility ultimately installed a ChemScan UV-2150/S Analyzer at two of its plants, making it possible to monitor and control chloramination without needing multiple instruments.

Result:

The system has provided online chloramination analysis at the two plants for a number of years, while requiring only routine maintenance. “It’s probably the best thing we ever purchased since I’ve been here,” says Scott Pavlik, water quality operations manager. “We’re happy to have something so reliable.” 800-665-7133; www.in-situ.com