Interested in Distribution?

Get Distribution articles, news and videos right in your inbox! Sign up now.

Distribution + Get AlertsIndustrial dairy turns to chopper pump system to recirculate foul air

Problem

Hollandia Dairy, one of California’s oldest independent dairies had a buildup of odorous septic sludge in a 35,000-gallon bolted steel equalization tank. Several times, the tank had to be drained, a time-consuming process. The side-entry mixer could not mix the tank sufficiently.

Solution

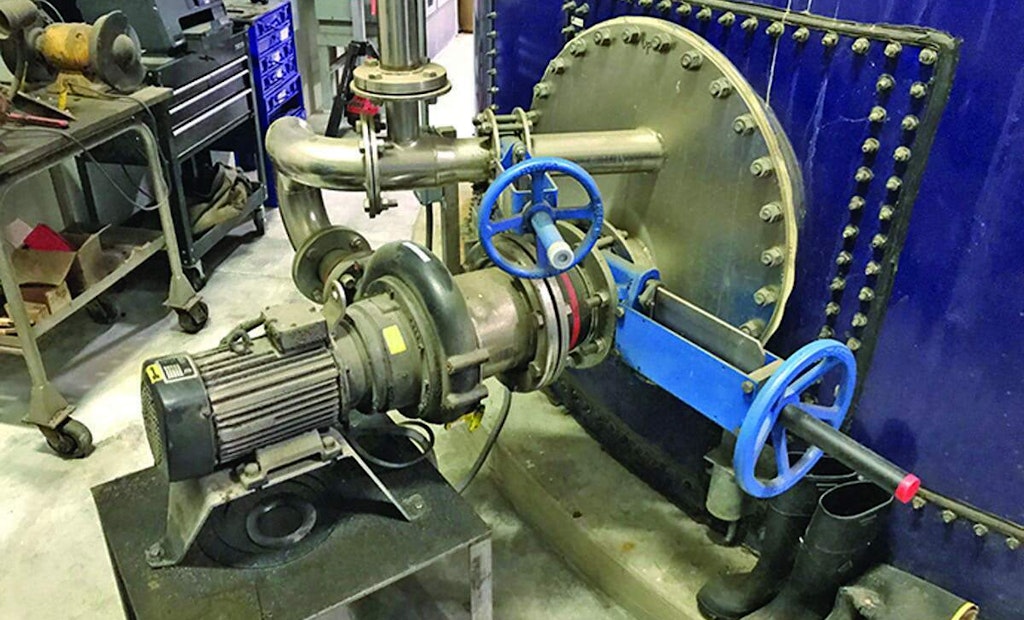

A Landia AirJet including the chopper pump was installed to recirculate the foul air from the top of the tank down through the wastewater, scrubbing out the sulfur to eliminate odor issues. The AirJet is a compact, self-priming propeller aerator. The air, and thus oxygen, is automatically sucked down through a hose; a rotating propeller releases it as bubbles. It combines mixing and aeration to keep effluent fresh, providing additional aeration at peak loads.

RESULT:

There are no more foul odors. The operators do not have to add chemicals to the tank, and there is also no need for energy-intensive blowers. With reduced pH, the tank contents no longer go septic. 919-466-0603; www.landiainc.com

Raw water pumping station increases drinking water production

Problem

The National Aqueducts and Sewerage Institute in Panama decided to build a new raw water pumping station to increase production at the drinking water treatment plant that serves about 60,000 people.

Solution

Reliability was important. The new pumping station extracts water from the Changuinola River and filters out the high sediment content. The water is then pumped to the treatment plant about 1.25 miles away. The project included large PRIMEX panels that control four 350 hp water pumps and seven 5 hp sand pumps. PRIMEX also provided variable-frequency drives with line reactors, a 1,600 amp main switch, a PRIMEX pump controller and extensive remote monitoring via Pump Watch system.

RESULT:

The new pumping station increased production, ensuring a reliable supply of sediment-free drinking water. 888-342-5753; www.primexcontrols.com

Chopper pumps specified to solve clogging issue at casino

Problem

When the wastewater treatment plant for a casino resort started having escalating clogging issues with their influent pumps, they reached out to PumpMan SoCal for a solution.

Solution

A pair of Barnes Sithe chopper pumps with Envie3 premium efficient IE3 submersible dry pit motors were selected. The heat-treated 440C stainless steel slicing blade and striker plate reduce solid size and pass even the toughest solids in the waste stream. The submersible dry pit motor with closed loop glycol cooling system allows pumping levels to be lowered since the motor no longer needs to be submerged for cooling. This minimizes scum and debris matting at the surface and even simplifies tank cleaning operations. The large stainless steel lifting handle eases pump removal and eliminates the risk of the pump falling from handle failure. A single plug-and-play cord simplifies wiring and eliminates small sensor cables. The slotted horizontal discharge easily adapts to ANSI and ISO/Metric quick removal systems. The striker plate clearance is adjustable with simple shims, allowing periodic adjustment to extend the life of the cutting components and clog-free operation. All seals, O-rings and bearings are standard, which simplifies sourcing and keeps parts costs down.

RESULT:

The pumps solved the clogging issues and continue to perform as advertised. 201-214-2259; www.pumpman.com